Buy

Selection, contracting and monitoring of suppliers and sub-tiers to ensure purchased products and services meet final customer requirements and suppliers continually raise their performance levels.

The Supplier Capability Assessment (SCA) is provided by the IAQG to help organizations continuously evaluate and improve the capability of their Supply Chain processes.

It is also provided to help customers to assess the capability of their suppliers during the selection process or later during the entire contract life, to identify possible areas of improvement and launch necessary actions e.g., supplier development plan.

Using SCA, an organization can evaluate its current level of capability or that of its suppliers and set clear targets for improvement. SCA can be successfully used by organizations either for their entire life cycle and all their products or services, or for some specific topics and activities only.

Note – For the self-assessment of its own Quality Management System, an organization can use the Aerospace Improvement Maturity Model (AIMM).

AIMM provides the expected outcomes derived from the 9100 Standard and the associated criteria to evaluate the level of maturity in achieving those outcomes, on scale from 1 to 5.

AIMM is intended for certified, as well as non-certified organizations. AIMM is organized in 26 modules; an assessment does not need to include all modules but can be limited to those of higher significance or priority to the organization itself.

This guidance describes the elements for a basic Supplier Quality Management System (SQMS) for managing a supplier’s performance and product conformity. It is applicable to any company in the supply chain with an emphasis on companies who may not have a complete SQMS in place or a new company to the aviation, space and defense supply chain. It contains basic elements that should be utilized (as applicable to the type of business) to ensure product conformity of materials and/or services received from their suppliers.

Most regulatory agencies and Buyers of products or services in the aviation, space and defense industry, have requirements that an organization they do business with has a Supplier Quality Management System (SQMS) that includes documented processes and procedures for managing their suppliers. Some of the basic elements for an SQMS should include but not be limited to processes to address:

- Flowdown of quality requirements

- Supplier Pre-production Planning

- Production Readiness

- Purchased Product Verification

- Supplier Performance Monitoring

- Supplier Surveillance

The guidance material is written from the perspective of a customer or purchasing organization, referred to as the “Buyer”.

There are modules related to Supplier Quality Management Basics in the Aerospace Improvement Maturity Model (AIMM). AIMM can help to evaluate the maturity of your QMS in managing this topic in relation to the requirements of the IAQG 9100 Standard. See AIMM modules 8.4.1Control of Externally Provided Processes, Products, and Services – General, 8.4.2 Type and Extent of Control of Externally Provided Processes, Products, and Services, and 8.4.3 Information for External Providers

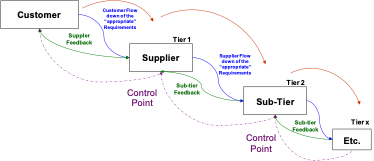

As with many industries, the aerospace and defense industry continues to increase the amount of work outsourced to suppliers, from the manufacturing of components to the building of modules and sub-assemblies. This trend has resulted in a very complex supply chain, making customers increasingly dependent upon their supplier’s ability to manage their sub-tiers. The Supplier Quality Management Basics in this SCMH “Buy” Section discusses some of the key elements for managing supplier quality. This guidance including an assessment process is designed to increase the robustness of sub-tier management throughout the supply chain.

The intent of this guidance is to drive advancements in the Supplier’s Sub-tier management system. The foundation is based on the requirements of the IAQG Standard 9100 for the purchased product.

There is a module related to Sub-tier Supplier Control in the Aerospace Improvement Maturity Model (AIMM). AIMM can help to evaluate the maturity of your QMS in managing this topic in relation to the requirements of the IAQG 9100 Standard. See AIMM module 8.4.1 Control of Externally Provided Processes, Products, and Services – General

IAQG standards AS/EN/JISQ/SJAC 9100, 9110 and 9120 require every organization to continuously improve their performances and determine actions to ensure these performances are in line with targets defined by internal and external stakeholders.

IAQG Product and Supply Chain Improvement Strategy Stream has identified a list of most commonly used Key Performance Indicators (KPIs) covering the main domains of the supply chain (‘Customer metrics’, ‘Engineering and Product Development’, ‘Program Management’, ‘Manufacturing and Production’, ‘Supplier Management’, and ‘In-Service – feedback from operations’).

Use of these KPIs should support harmonization and reduction of customization of these KPIs between the entity establishing them and its different internal and external customers.

Each KPI is listed on a single page and provides the following information: KPI Name; KPI Abbreviation; KPI Description; KPI Formula; KPI Unit of measure; and Detailed explanations.

“SCMH Procurement Engagement” is an initiative designed for the Buyer function. The guidance is based on the existing SCMH guidance materials. The aim of this guidance is to improve buyers’ knowledge and awareness of the supply-chain quality activities and available best practices in the SCMH.